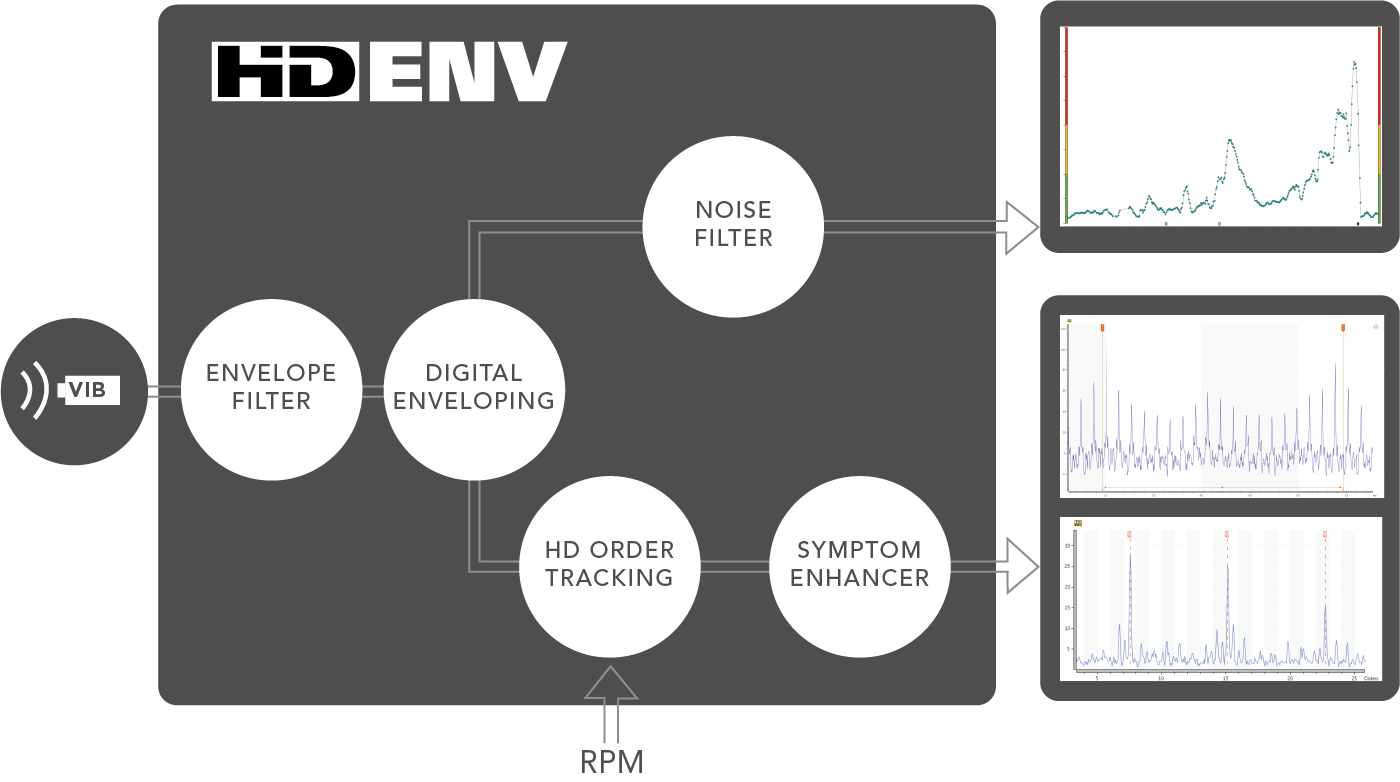

HD ENV® vibration enveloping technology

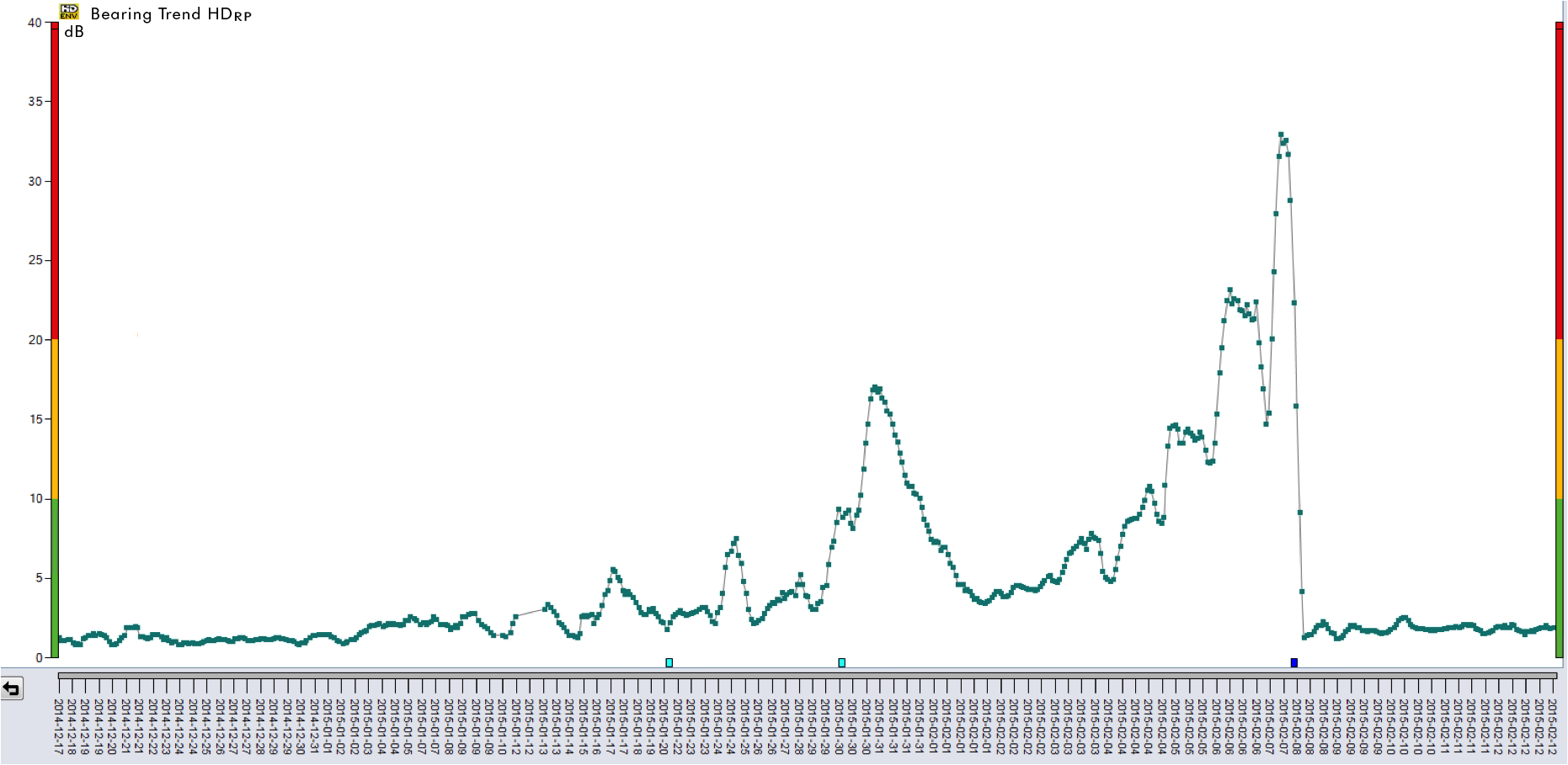

The HD ENV® vibration enveloping technology enables the detection of gear and bearing faults very early on in the damage process, making it possible to monitor the development throughout the stages closely.

Vibration monitoring with HD ENV enhances the processing and presentation of vibration data to users. The unique preciseness and clarity of spectrums and time signals pinpoint the location, nature, and extent of emerging damage with great accuracy and superior forewarning times.

Benefits

-

Vibration enveloping on a whole new level and an ideal complement to conventional vibration techniques.

-

Detects, at a very early stage, machine problems generally hard to find in good time with non-enveloping techniques.

-

Utilizes cleverly engineered algorithms for digital signal processing to obtain optimal data for trending purposes.

-

Monitors applications in a vast RPM range.

-

Integrates easily into existing industrial infrastructures using existing vibration transducer installations.

Technical description of vibration enveloping technology

Capable of detecting at a very early stage such machine problems that are generally difficult to find in good time with non-enveloping techniques – for example, gear damage and bearing damages – the method utilizes cleverly engineered algorithms for digital signal processing to obtain optimal data for trending purposes.

Signals buried in machine noise are revealed through high-definition digital enveloping, extracting and enhancing the signals of interest from the overall machinery vibration signal while preserving the true highest peaks. HD ENV can be used to monitor applications in a very broad RPM range.

Input data

To perform overall machine condition trending, a signal from a vibration transducer and an rpm measurement is needed. For analysis and symptom trending, gear and bearing data are also required.

Filters and other options

A number of predefined filters are available to detect damages or anomalies in different stages of development; two of which are specifically designed for bearing monitoring and the others for special applications, both bearing and non-bearing applications.

Noise filter: Randomly occurring high readings which may cause false alerts are filtered out by means of the random impact rejection algorithm.

RPM fluctuations are handled with HD Order Tracking, see below.

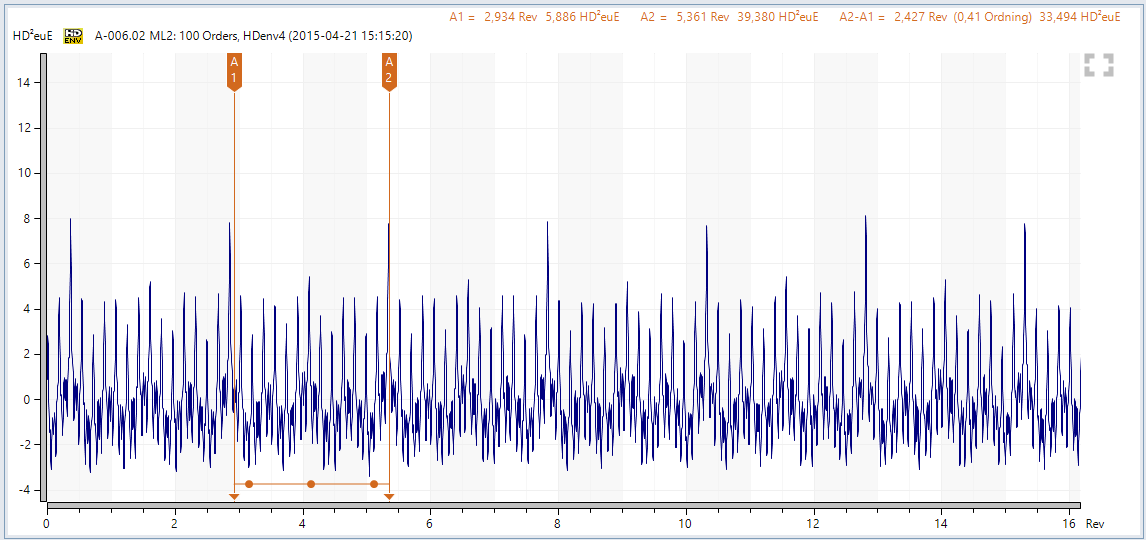

The Symptom enhancement algorithm looks for repetitive impacts in the time domain. As a result, random signals are suppressed and repetitive signals enhanced. The output is an HD ENV Time signal, where relevant bearing and gear data can be displayed.

Output data

-

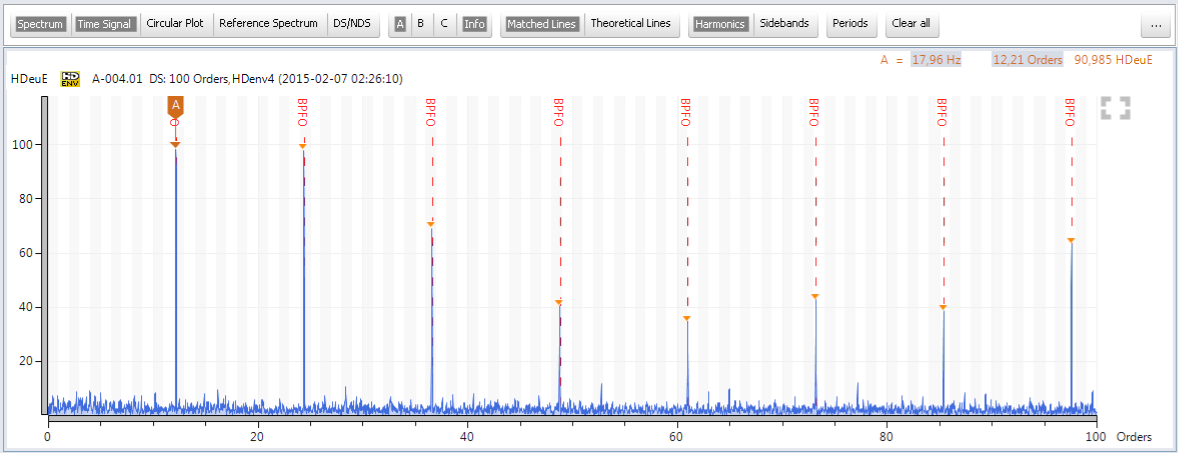

HD ENV Spectrum

HD ENV Spectrum is the result of applying FFT algorithms on the HD ENV Time signal. The HD ENV Spectrum is useful to determine (1) where in the bearing a possible damage is located, and (2) the severity of the damage. It is also useful for trending purposes (applying symptom and band values).

HD Order Tracking

On machinery operating under variable speed, analysis with High Definition Order Tracking provides reliable data and crystal-clear measuring results even when RPM varies greatly during the course of measurement. More and more machines are speed-controlled; for example, compressors with variable speed drive (VSD) where RPM changes very quickly. Order Tracking is applicable in a vast RPM range, from just a few to thousands of revolutions per minute.

HD Order Tracking is approximately ten times better than traditional order tracking algorithms when RPM is not perfectly stable.

The method uses multiples of rotational speed (orders), rather than absolute frequency (Hz). The purpose of using orders is to lock the display to the rotational speed (1X) and its multiples, meaning that the ordered components in the spectrum always remain in the same position even if the rotational speed varies during measurement.

Two or several spectra from the same machine with variable speed can, therefore, more easily be compared if they are expressed in orders. With order tracking, the frequency range always covers the symptoms of interest, regardless of the rotational speed of the machine.