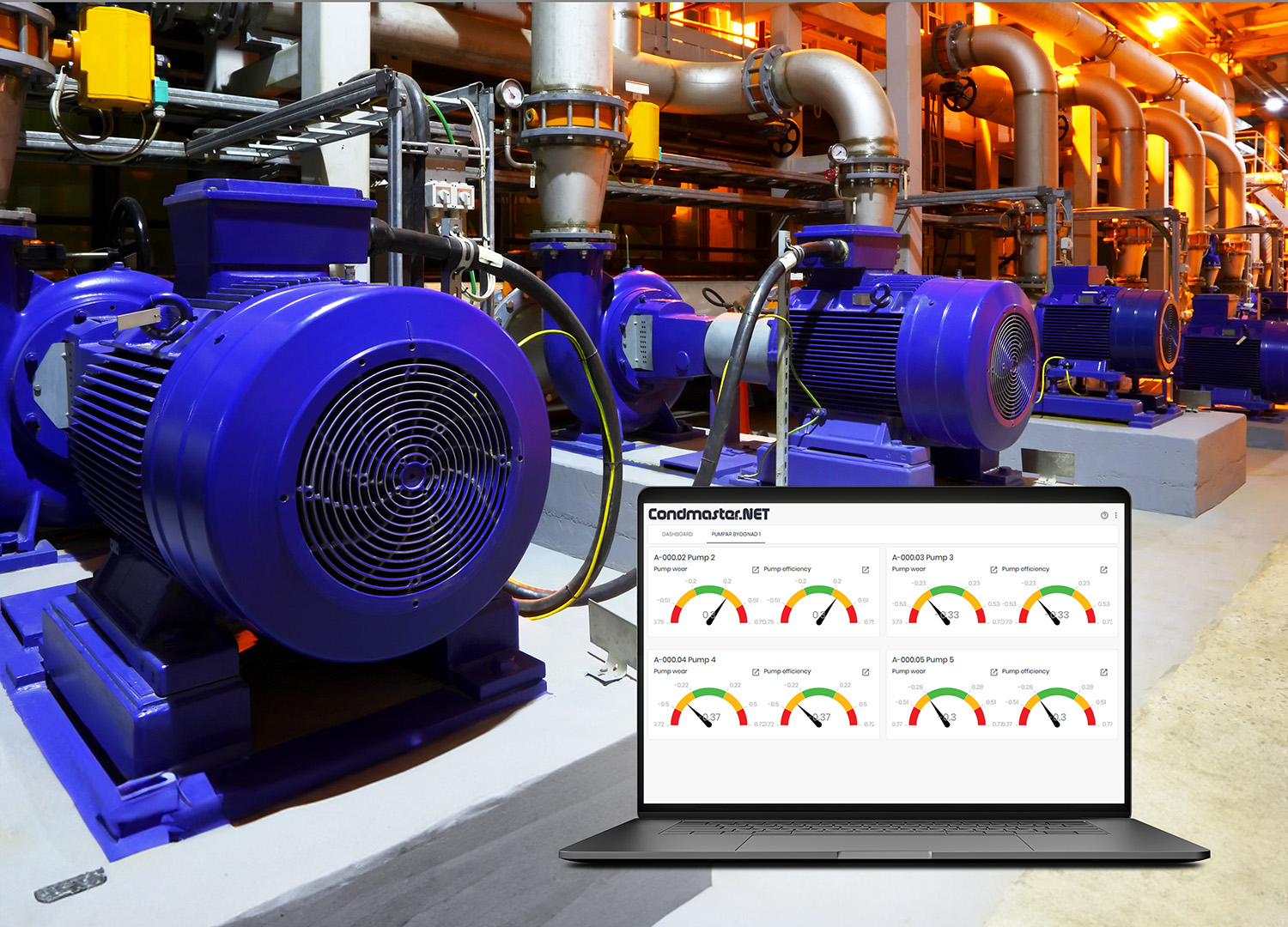

SPM Instrument introduces impactful process optimization for centrifugal pumps

SPM Instrument is excited to introduce its latest process optimization solution, designed for monitoring the performance of centrifugal pumps. Based on SPM’s patented HD technology, this innovative solution can boost energy efficiency, extend the service life, and dramatically enhance the overall operating economy of this widely used industrial equipment.

Best Efficiency Point–the sweet spot for optimal pump performance

Pumps account for a significant part of the world's energy consumption–in some industrial sectors and in municipal systems, they are the single largest energy user. The key to optimal efficiency is BEP (Best Efficiency Point), a critical operating parameter in centrifugal pump systems. Operating at or near BEP paves the way for efficiency and energy savings, reduced vibration and noise, lower maintenance needs, and extended equipment life.

SPM’s pump performance monitoring solution determines BEP based on factual, real-time data, rather than theoretical calculations and manufacturer specifications with built-in tolerances, which also do not consider that wear on pump parts and piping causes BEP to change over time.

The monitoring solution utilizes high-resolution shock pulse and vibration data to match the system and pump curves to operate at the BEP. By precisely controlling the pump’s operation, energy consumption can be fine-tuned, and overall pump performance enhanced.

Depending on business priorities, the solution allows operators to monitor either energy efficiency and incipient cavitation, or pump wear. A web-based dashboard serves as an identification tool for BEP. It visualizes readings throughout the pump’s flow rates, clearly and intuitively indicating the best efficiency point.

Process optimization and condition monitoring – a powerful duo

Expanded with additional sensors, the measuring system can also be used for condition monitoring to identify early signs of mechanical problems in the pump and its assembly. Combined, process optimization and condition monitoring enable businesses to get the most out of both the process and the production equipment, which can significantly enhance operations and impact the bottom line.

It is not just one or the other–it is what happens when implementing both.

For more information, contact your nearest SPM representative, or

info@spminstrument.se

+46 (0)152 225 00

Downloads

Technical Solutions

TS033 – Centrifugal pump (process optimization)| Filename/description | Language | Size | Modified | |

|---|---|---|---|---|

| TS_033B.pdf | English (United Kingdom) | 1 MB | 7/3/2025 | |

| Technical solution, optimized centrifugal pump performance (process optimization) | ||||