SPM Instrument introduces knife wear monitoring for wood chippers

Extending its range of process optimization solutions, SPM Instrument now launches knife wear monitoring for wood chippers. The knife system is the heart of the chipper, and its effectiveness in producing premium-quality wood chips impacts the entire downstream process.

Profitable pulp production begins with high-quality, even-sized wood chips. In pulp mills, all the raw material passes through the wood chipper, and its ability to deliver top-grade chips is paramount to digester or refiner performance, pulp quality, raw material yield, and end product quality.

The critical role of knife condition in wood chip quality

In the chemical and mechanical pulping process, the size distribution of wood chips is crucial for a smooth process in subsequent stages. Variations in chip thickness lead to uneven penetration of cooking liquors and, as a result, less efficient impregnation.

In addition to wood quality, the chipper knife system has the greatest impact on final chip quality. Keeping the wood chipper running with knives in good condition is the most effective and cost-efficient way to maximize pulp yield and quality. Dull or damaged knives typically result in increased and inconsistent chip sizes, leading to lower-quality pulp. Contaminants such as rocks can damage the knives, particularly during winter. Blunt blades also cause greater impact forces on the machine. However, the ideal time to replace the knives is not easily identifiable, and this assessment often relies on operator experience.

Informed decisions, better results: boosting quality and minimizing waste

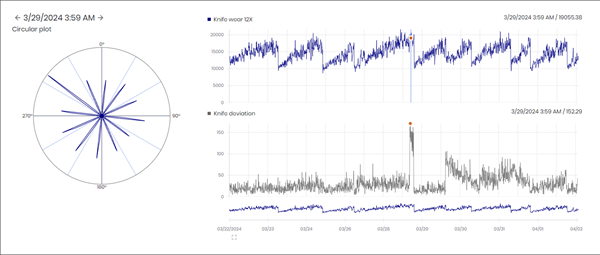

SPM’s knife wear monitoring solution provides insights into the condition of chipper knives and offers decision support on managing chipper knife replacement.In a web-based dashboard, clear and easy-to-understand graphs indicate whether a knife is damaged, becoming dull, detached, or missing from the knife holder:

Benefits of monitoring knife sharpness and identifying situations where one or more knives deviate from the others include:

- production of wood chips with a more uniform size and thickness

- minimized rejects and maximized accepts

- higher raw material yields

- higher digester throughput – examples show increases in the order of 10%

- condition-based knife replacement

Karl-Johan Ericsson, Maintenance Manager at Swedish pulp mill Aspa Pulp: “The system is very stable and the results are reliable. It tells the truth about the status of the process and the knife condition in real time. The web app shows customized graphs on a screen in the control room, which is super easy to understand and very helpful to the operators.”

Knife wear monitoring with innovative HD technology

Wood chippers are subject to extensive vibrations and impacts arising from logs hitting the chipper disc, making them a “noisy” environment for data acquisition. The random infeed of logs is a further challenge. SPM’s online system Intellinova Parallel EN and patented HD technology algorithms handle these factors with exceptional results.

Using the same equipment, chipper knife monitoring can be cost-effectively combined with monitoring the mechanical and lubrication condition of the chipper’s rotating parts, such as main bearings, gearboxes, viscous couplings, and motors.

SPM has previously launched process optimization solutions for tumbling mills and vibrating screens in the mining and cement industries.

For more information, contact your nearest SPM representative, or

info@spminstrument.se

+46 (0)152 225 00

Downloads

Technical Solutions

TS030 – Wood chipper (process optimization)| Filename/description | Language | Size | Modified | |

|---|---|---|---|---|

| TS_030B.pdf | English (United Kingdom) | 2 MB | 11/24/2025 | |

| Technical solution, wood chipper knife monitoring (process optimization) | ||||

| TS_030C.pdf | German (Germany) | 2 MB | 11/24/2025 | |

| Technical solution, wood chipper knife monitoring (process optimization) | ||||

Customer Case

Customer case – Aspa Pulp (process optimization)| Filename/description | Language | Size | Modified | |

|---|---|---|---|---|

| CC_012B_Aspa Pulp.pdf | English (United Kingdom) | 1 MB | 11/24/2025 | |

| Customer case – Aspa Pulp, SE – Wood processing (process optimization) | ||||

| Filename/description | Language | Size | Modified | |

|---|---|---|---|---|

| CC_011B_FollaCell.pdf | English (United Kingdom) | 904 kB | 11/24/2025 | |

| Customer case – FollaCell, NO – Wood processing (process optimization) | ||||