Condition monitoring of refiner bearings

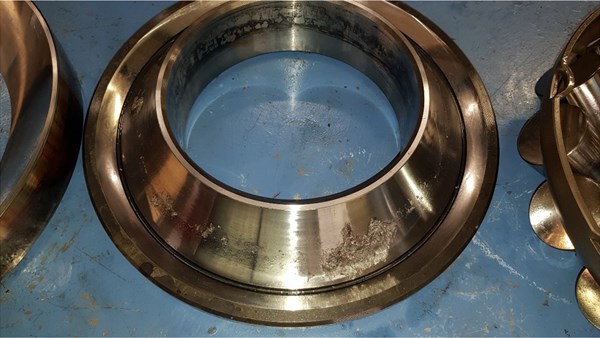

Norwegian pulp mill MMK FollaCell AS monitors critical equipment with the Intellova Compact online system. This case study describes three individual bearing damages found in two refiners.

Due to the refiner design, the conditions for measuring these bearings are not optimal, and the damage development process is often fast. Although the measured signal is dampened, it was still possible to detect these three damages in time for planned bearing changes using HD condition monitoring technology.

Download full case study

Case Study

CS028 - Refiner - FollaCell| Filename/description | Language | Size | Modified | |

|---|---|---|---|---|

| CS_028B_Refiner_FollaCell_NO.pdf | English (United Kingdom) | 6 MB | 4/19/2022 | |

| This case study describes three cases of bearing damage detected on the aft bearings of two refiners in a Norwegian pulp mill. | ||||

HD Technologies

High-definition condition monitoring technologies provide exceptional pre-warning times, maximizing the planning horizon for maintenance and repairs. In turn, this enables fully utilizing asset life, cutting repair costs, and minimizing the consequences of unplanned downtime.

Intellinova online systems

With Intellinova, our unique HD condition-monitoring technologies can be fully utilized to successfully provide earlier warning of mechanical problems than any other monitoring technology.

Pulp and paper

Condition monitoring is a cornerstone in the asset management of pulp and paper plants. Having control of the operating condition is a must to optimize plant profitability.